For centuries, Sri Lanka has been renowned for its exquisite gemstones, sought after by collectors and connoisseurs worldwide. While modern technology has transformed the gem-cutting industry, the island’s traditional methods still hold a special place in its heritage. Among these ancient techniques, the banku pattaley stands out as a remarkable testament to the skill and craftsmanship of Sri Lankan lapidarists. Yet, despite its historical significance, this method is slowly fading into obscurity. Even within the gem industry, many have never heard of the banku pattaley.. a tool that was once an essential part of Sri Lanka’s gem-cutting legacy.

At Ceylon Gem Chronicles, we were the first to bring this lost art back into the spotlight in our very first Chronicle. Later, we followed up with a full process video, documenting every step of this fascinating technique. Through our research and storytelling, we uncovered a technique that only a handful of experienced lapidarists still remember. The banku pattaley is not just a relic of the past, it is a dying art, and without efforts to preserve it, this invaluable tradition may disappear entirely.

Watch the full video where we first discovered the Banku Pattaley here:

What is the Banku Pattaley?

The banku pattaley is a traditional, manually operated gemstone cutting and polishing apparatus that has been used in Sri Lanka for generations. Unlike modern cutting methods that rely on diamond powder, the banku pattaley uses a unique silica-based compound derived from burnt paddy husk. This method requires exceptional precision, patience, and teamwork, making it a rare and fascinating art form that has survived through the ages.

A Two-Person Craft

One of the most distinctive aspects of the banku pattaley is that it is a two-person operation. While one artisan skillfully cuts and polishes the gemstone on a spinning copper plate, another person turns the wheel manually to maintain a consistent speed. The person turning the wheel does so by following the hand gestures of the cutter, adjusting speed, stopping, or even reversing direction as needed. This requires immense skill and experience, as precise control is crucial for achieving a flawless cut and polish.

The Role of the Faceter

One striking feature of traditional faceting in banku pattaley is the absence of numerical markers. Modern faceting machines use calibrated measurements to ensure symmetry, but here, the faceter relies on intuition and expertise. Without any guiding numbers, these artisans shape the stone entirely by hand, making each piece a testament to their mastery. This method not only preserves an organic, handcrafted quality in the gems but also highlights the depth of their skill.

The Role of Silica in Cutting and Polishing

Unlike modern gem-cutting techniques that rely on diamond powder, the banku pattaley utilizes a specialized silica compound to cut and polish corundum gemstones, including Sri Lanka’s famous sapphires. This silica is derived from burnt paddy husk, which undergoes a fascinating transformation before it becomes suitable for gem cutting.

- Burning the Paddy Husk – The husk is burned at approximately 1000 degrees Celsius, leaving behind a fine ash that is rich in silica.

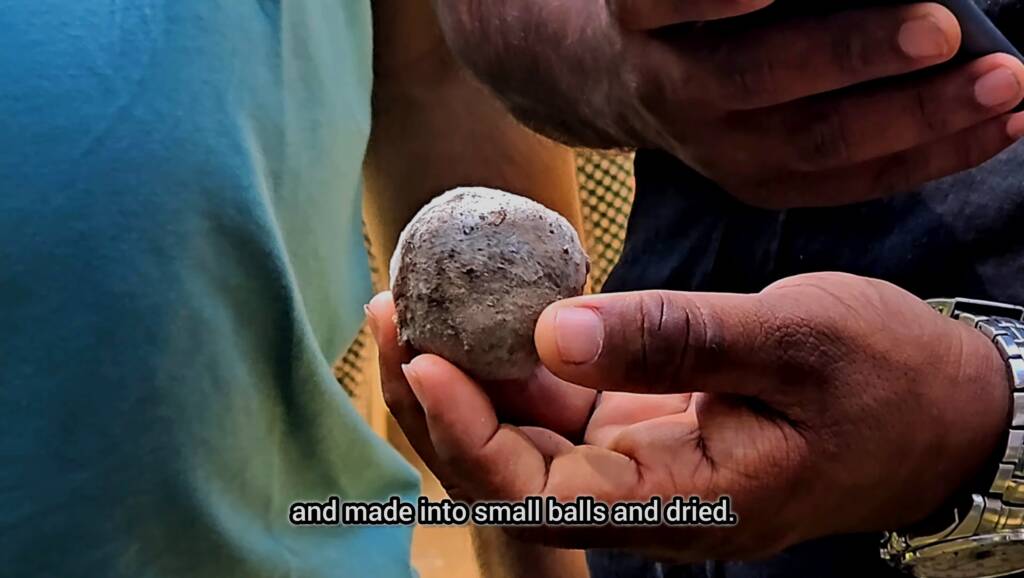

- Forming Silica Balls – The silica ash is then mixed with cooked rice to form small balls, which are left to dry under the sun.

- Preparing the Cutting Compound – When needed, these dried silica balls are dissolved in water. The resulting mixture separates into two layers:

- Larger, heavier particles settle at the bottom, which are used for cutting the gemstone.

- Lighter particles remain near the surface, which are used to polish the gemstone to a flawless finish.

The Science Behind the Cutting Process

Silica falls under the category of quartz and ranks at 7 on the Mohs hardness scale, while corundum (which includes sapphires and rubies) ranks at 9. Despite this difference in hardness, the banku pattaley is still able to cut and polish corundum effectively. This is due to the intense heat generated when the corundum is pressed against the spinning copper plate. The heat causes the surface of the corundum to momentarily soften, allowing the silica particles to shape and polish it with remarkable precision.

Superior Polish and Lasting Approval

Many experienced lapidarists from older generations believe that the banku pattaley produces a superior polish compared to modern cutting methods. This widespread approval suggests that while technology has advanced, traditional craftsmanship still holds unmatched value in the gem-cutting world.

A Legacy at Risk of Being Forgotten

The knowledge of the banku pattaley is vanishing. Today, even those within the gemstone industry rarely know of its existence. Fewer still have ever seen one in use. It was Ceylon Gem Chronicles that reignited interest in this forgotten craft, shedding light on its history and significance in our first-ever Chronicle. Later, we took it a step further by producing a complete video detailing the full process, ensuring that this knowledge is documented for future generations. But without efforts to preserve this art form, the remaining masters of this technique will be the last to carry its secrets.

Preserving a Time-Honored Tradition

Despite the advancements in gem-cutting technology, the banku pattaley remains an integral part of Sri Lanka’s gem heritage. This traditional method showcases not only the ingenuity of Sri Lankan lapidarists but also the deep respect for craftsmanship that has been passed down through generations.

At Ceylon Gem Chronicles, we are committed to documenting and preserving the rich history of Sri Lanka’s gem industry. The banku pattaley is a shining example of how traditional techniques continue to shape the world of fine gemstones. As we delve deeper into these ancient methods, we invite you to join us in celebrating the artistry and dedication that make Sri Lanka’s gems truly extraordinary.

Stay connected as we continue to explore the untold stories of Sri Lanka’s gemstone legacy.

Complete Guide to the Banku Pattaley: